17 Dec Embroidered vs Vinyl Printed Workwear

Embroidered vs Vinyl Printed Workwear

We often have customers ask us for embroidery. This used to be the go-to method for garment branding, but these days there are so many other options. The new DTG (Direct to Garment) machines offer a really viable alternative for bulk orders and offer a full colour solution that screen printing struggled with.

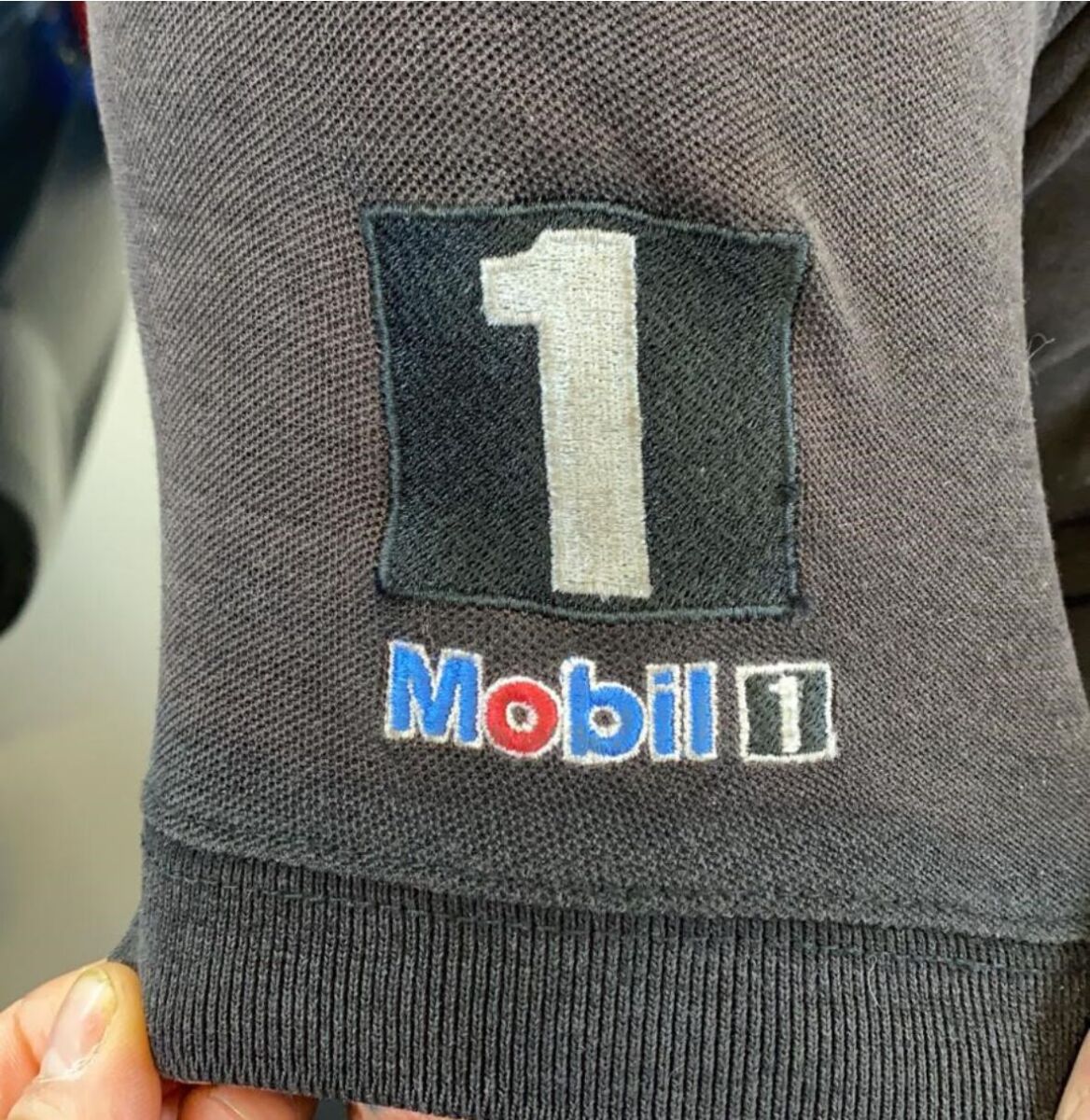

We offer three types of branding onto textiles – and there are good reasons why this does not include embroidery. Perhaps it still has a place on knitted hats, but to be honest, clothing branding has come on a lot that there is not much to recommend embroidery over vinyl printing these days.

Embroidered vs Vinyl Printed Workwear:

- Is a method where an image is stitched onto a fabric – this is the method and the only method.

- It is priced by the thread, so for individual or short runs, the set up cost can be prohibitive

- It creates a rear patch through which the stitches are fixed. This can cause irritation and nipple rash

- It also creates sag on light weight fabrics

- The very method of its stitching makes it unsuitable for modern stretchy fabrics

- It is liable to bunching and fading over many washes, especially on cotton

- Your design will not have crisp edges as the threads lead to bluring on small lettering

- There are limitations on multi-colour logos or very small lettering

- It works well on woollen and fleece products

- Hygiene can be an issue for sterile situations as germs/matter can be caught in the threads

- And most importantly, many outer garments have their waterproofing damaged by use of embroidery

- If you have never seen a commercial embroidery machine in action, take a look here

Vinyl Printing vs Embroidered Workwear:

- This method has really developed over the years, with lots of different types of vinyl made for different types of garment

- We use a leading brand called Siser, which has a longer life and does not crack

- Vinyl printing is really better for smaller designs and logos. It can feel stiff on larger single patches

- It sits on the surface of the garment so there is no internal irritation

- Ideal for short runs or single items as there is no set up fee.

- Very cost-effective for print-to-order or on-demand

- Works best for single or double colour overlay – not suitable for full colour unless printed onto vinyl

- Not suitable for woollen products and some fleece – although recycled microfleece responds well

- There are vinyls suitable for stretchy material

- Adheres well to light fabrics

- Lots of lovely colours and specialist finishes such as mirror, glitter etc

- Washes well at modern low temperatures, do not tumble dry

- Hygienic to wipe or spray with antibac.

- Works well on caps and bucket hats

At Griffin Designs we offer:

- Block cut vinyl printing – using the new Siser stretch vinyls – ideal for single or dual colour designs

- Printed vinyl – full colour designs on nearly all types of fabrics

- Ink transfer system using the Uninet colour – so detailed it can even print photos

So whatever type of garment you want printed, we have you covered.

If you have any doubts or would like to see a sample of our work, please get in touch.